Introduction:

The following information is about Spirulina Farming and Its Growing Methods.

Spirulina is a micro-algae, which is found growing naturally in warm alkaline lakes. It is blue-green in colour and possesses amazing qualities of super food. It is different from other algae because it can grow and survive in conditions where the other algae cannot. Basically Spirulina is a single celled structure or organism which has the ability to convert sunlight to micro-nutrient life energy. The Spirulina gets its name from the spiral shape it has and it is believed to be one of the earliest life forms that originated over 3.6 billion years ago. Micro-algae are one of the smallest organisms on earth and are considered to produce 60% of the earth’s oxygen. They have incredible resistance and robust cell wall. Spirulina is an ingredient on which flamingos survive and it gives them their distinct pink colour. Spirulina can be grown in photo bio-reactors or man-made artificial lakes, but it should be clearly noted that naturally growing spirulina in lakes and oceans should not be harvested otherwise this would cause imbalance in the ecological biodiversity.

Growing Conditions for Spirulina Farming

The minimum temperature for growing Spirulina is 20˚C, but it is known to grow within a temperature range of 25-37˚C. Spirulina is grown in water and doesn’t need any soil for growing. Spirulina needs minerals and chemicals for growing and the pH of the growth medium should be around 8-11. Generally a pool is created artificially or a container is used to grow Spirulina. During the initial stages of growth Spirulina needs shade and is provided with a temporary cover. If there is less sunlight and low solution concentration, then Spirulina struggles to grow. The lake or container for growing Spirulina should be shallow.

Rain is believed to dilute the growing culture and alter the pH; dust and sand tangle in the Spirulina and make it heavy such that it sinks to the bottom; flies and insects should be avoided; direct sunlight at initial stages of growth has to be prevented. A green house arrangement is perhaps a solution for all the above mentioned problems during Spirulina farming. It increases the temperature and decreases evaporation and cross-breeding of micro-algae.

Area requirement for Spirulina Farming

If Spirulina is grown in containers, then plastic containers are an ideal choice, else containers which are transparent would be good because they increase exposure to sunlight. For farming Spirulina on a large scale, pools or ponds are created with a variety of materials. A frame of wood, metal or sand sacks can be used as a structure for farming and this structure can be lined with tarpaulin, rubber sheets or polythene of high density. Building the growing structures for Spirulina should not be done with cement, else it should be taken care that cement doesn’t come into direct contact with Spirulina. The minimum pond size for commercial cultivation of spirulina is 3 to 4 m wide and 100 m long. If farmed in smaller tanks, then the minimum dimensions of the tank should be 10 x 5 x 1.5 ft. The minimum depth of the culture medium should be 20 cm and the depth of the pool should be twice the culture medium depth.

Growth medium for Spirulina Farming

The culture medium for growing Spirulina is made of water and fertilizers. Any kind of water type can be used like the brackish water, rain water, fresh drinking water, etc. because the pH level maintained in the pond gets no competitors for Spirulina and also at this level of pH no parasites or germs survive in the medium. The water for spirulina farming should be free from heavy metals otherwise they will be absorbed by spirulina.

The fertilizers required for spirulina farming are:

- Sodium bicarbonate

- Citric acid

- Urea

- Potassium nitrate

- Sodium chloride

- Potassium dehydrogenate phosphate

- Iron sulphate

- Magnesium sulphate

- Large scale cultivation needs calcium in the form of lime, gypsum or calcium chloride

Fertilizers used for spirulina farming should be of food grade quality and should be soluble in nature, unlike the chemicals for agriculture which are granulated slow release in nature. Addition of micronutrients will add extra nutritional value to spirulina and enhance its growth.

All the spirulina farming enterprises use a standard way of preparing the culture medium and this is based on the Zarouk medium specifications, which tells that NPK are used in large quantities; sulphur, magnesium and calcium in lesser quantities and other minerals like iron, boron, copper in very little quantities (almost micro measurements).

Other basic requirements for Spirulina Farming

For growing spirulina, the mother culture has to be introduced into the medium initially and the solution should be agitated each day for half an hour with a long stick. This has to be done for one week in the beginning.

An apparatus for testing the pH level of the medium is needed because spirulina grows in highly alkaline medium and maintaining the pH is important. Small scale spirulina farms (containers) generally use litmus papers for testing the pH of the medium.

After spirulina has grown, it needs to be filtered from the solution and therefore filters are required during harvesting spirulina. Generally cloth of density 30-40 microns made up of polypropylene or nylon is used for this purpose.

A device is required to agitate the growing medium so as to facilitate sunlight distribution evenly to the entire contents of the tank/pool. If this is not done, then spirulina gathers at the top of the growing medium, where sunlight is adequate and the spirulina at the bottom receives less light and will eventually die. For manually agitating the medium a stick or broom, which is thoroughly cleaned is used otherwise a mechanical pump would also be a better option to agitate large spirulina faring areas.

If the cultivation is done on a large scale, then a laboratory assistance is taken to observe the growth of spirulina else a simple microscope would be sufficent for inspecting the culture growth.

It is important to grow spirulina in a neat and hygienic environment, therefore the surroundings have to be maintained properly at all times. Labourers are also given hand gloves while handling the equipment for spirulina.

Production and Harvesting in Spirulina Farming

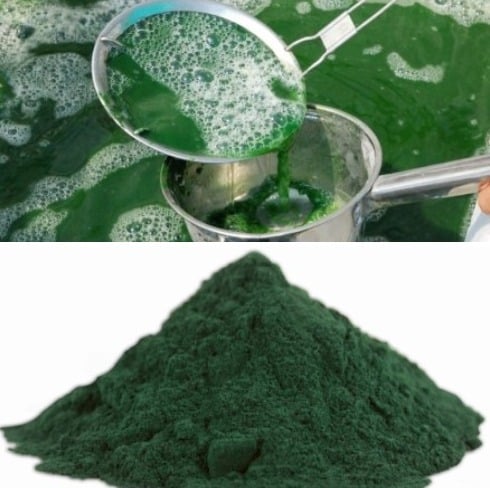

Spirulina reproduces from previously grown mature culture under proper conditions. It is believed that it doubles every 48 hours. The culture medium is made and the mother culture is released into the pools. A mechanical paddle wheel agitator can be used to agitate the mixture for large farms and this should be done for 15 minutes every hour for almost 10-12 days. The dark green colour concentration of the culture medium indicates that the spirulina is ready to be harvested.

Small plastic buckets and filters are used to harvest spirulina. The culture is filtered and then put in a muslin cloth and pressed under a weight of 50 kg to remove all the excess water present in it.

To store spirulina for longer time, it has to be dried and stored in clean dry containers. Spirulina is put in machines to give it the noodle structure and then dried over a clean cloth under the sun for 2 or three days. If spirulina is dried under shade, then it may take 3-4 days to dry it completely. Electrical or solar dryers are also used for drying spirulina on a commercial level. Mechanical drying needs 40˚C for 16 hours or 60˚C for 4 hours. Once the spirulina is dry, it is grounded in machines to form a powder, which is now sent to the lab for testing.

It is estimated that 18 sq m of a spirulina culture tank can produce 150 g of spirulina per day. And the sale price of 1 kg of spirulina is around Rs 600-700.

Monitoring the process for Spirulina Farming

- The pools or ponds where spirulina is farmed should be cleaned every 4 to 6 months. All equipment used should also be cleaned after each use.

- Having multiple small pools is easy to manage and produce more spirulina rather than having a big pond for farming.

- Agitating the culture medium every 2 or 3 hours is necessary to keep up the photosynthetic activity otherwise the spirulina would gather at the top of the tank and cause harm to the one present at the bottom.

- Spirulina needs sunlight for its growth, but during the beginning stage it should be protected from strong sunlight. During the rainy season, artificial light is provided to compensate the sunlight required for its growth.

- Any decrease in the culture level should be immediately compensated. There could be a decrease in level of the medium due to evaporation and this can be measured using an instrument (ruler).

- The temperature of the area should be timely monitored such that it doesn’t fall below the minimum level.

- The pH and salinity of the culture medium should also be checked frequently otherwise there would be a chance of contamination.

- Density of spirulina can be indicated by the colour of the medium just before harvesting. Darker the medium, higher the density.

Read: HIBISCUS FARMING.

Read: TEAK WOOD FARMING PROJECT REPORT.

Very informative

Very nice ,though brief but informative

Very informative information

Is there an agency responsible for the oversight and management of commercial scale production of spirulina in Victoria, Australia?

Very informative