Poultry Farming Guide:

Introduction of Poultry Farming:

Poultry meat is an important source of proteins, minerals, and vitamins to balance the human diet. Specially developed varieties of chicken (broilers) are now available with quick growth & high feed conversion efficiency. Depending on the farm size, broiler farming can be the main source of family income. Poultry farming includes raising of various types of domestic birds commercially for the purpose of meat, eggs and feather production. The most common and widely raised poultry birds in the world are chicken. Again, these may be broiler chicken or layers. Commercial chicken farming is the most successful business in Asia and other parts of the world. Proper care of birds and farm management practices will result in decent profits in a short period of time. Basically, Broilers are raised for meat purpose whereas layers for egg production. Farmers can even go for back yard chicken farming or country chicken raising at home. Apart from meat and egg production, manure that produced in the farm has good market value. This manure can be used as organic compost in various field crops. If you are planning for a poultry farm on a small scale or large scale, first you should make a perfect plan that involves building sheds/housing to marketing. Follow the standard methods, visit some nearby poultry farms and make a note of their practices which will really help you in setting up a farm and succeeding. In this article, let us discuss broiler chicken farming.

Health Benefits and Nutrition Facts of Chicken Meat:

The following are some of the health benefits of consuming chicken.

- Chicken is high in Protein and helps in building muscles.

- Chicken is a natural anti-depressant.

- Chicken meat helps in preventing bone loss and cuts the risk of arthritis.

- Chicken meat is good for heart health.

- Chicken has magnesium that can help to cope with premenstrual stress.

- Chicken improves immune power.

- Chicken spikes testosterone levels due to zinc presence.

- Chicken helps in relieving stress.

- Chicken is best for growing children.

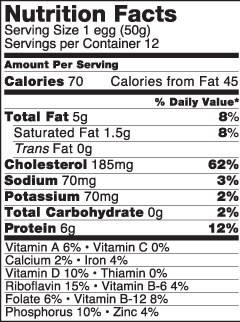

Nutritional Facts of Eggs

Top 10 Producers of Poultry in the World:

The Following are Top 10 producers of chicken in the world.

1. China.

2. The United States.

3. Indonesia.

4. Brazil.

5. India.

6. Mexico.

7. Russia.

8. Japan.

9. Iran.

10. Turkey.

The major Poultry Production States in India:

Andhra Pradesh, Telangana, Tamil Nadu, West Bengal, Bihar, Maharashtra, Punjab are major poultry production states in India.

Local Names of Poultry in Asia:- Murġā (Urdu), 닭,Dalg (Korean), Kukhurā (Nepali) , دجاجة dajāja (Arabic), Manok (Filipino),ไก่,Kị̀ (Thai), gà (Vietnamese), ニワトリ, Niwatori(Japanese), කුකුළු පැටව් (Sinhalese, Sri Lankan), Курица (Russian), Tavuk (Turkish), Ayam (Malay), مرغ خانگی (Persian), 鸡 (Taiwanese), Murgi (Hindi, Indian).

Local Names of Poultry in India:- Murgi (Hindi), Kodi (Telugu), கோழி, kozhi (Tamil), കോഴി (Malayalam), Koonkaad (Konkani), Murgi (Punjabi),କୁକୁଡାଛୁଆ, kukudachhua (Oriya), Kukura (Assamese), koLi (Kannada), Komdā (Marathi), Muragi (Bengali).

Main Types Of Poultry (Chicken):

- Broilers: These birds are raised for meat purpose.

- Layers: These birds are raised for egg production.

Other Poultry Birds:

Other than chickens, the following birds come under poultry group.

- Turkey.

- Quail.

- Ostrich.

- Duck.

- Pigeon.

- Peacock .

Advantages of Poultry Farming:

Well, there are many advantages of poultry farming, because of these benefits, many farmers across the world going the commercial poultry farming.

- Basically, poultry farming doesn’t require high capital for starting up as most of the poultry birds are not expensive.

- This can be started in a small space unless you are interested to go for commercial broiler farming on a large scale. These birds even can be raised in back yards.

- To start a chicken farming, it does not require a license as these birds are domestic, whereas quail birds require a license. The farm does not require much maintenance if proper cleaning methods or neatness is maintained. This also prevents some diseases in poultry.

- Poultry products have regular and huge demand globally. As these products are not expensive and provide fresh and nutritious food. It is very easy to market the poultry products as is there is an established market in all over the places.

- Poultry farming provides local employment opportunities and educated youth can utilize this opportunity to earn huge income. Poultry farming is also beneficial for rural women who are unemployed.

- Manure produced during the poultry farming can generate the income as well. However, If you are growing any field crops, this manure works as organic compost and produces more yield.

- If you are planning for commercial chicken farming, there are many loan schemes available from local banks and subsidies in local government schemes.

Main Requirements For Poultry Farming:

If you are planning for a commercial broiler farming, make sure to have enough land to build housing or sheds with ample clean water. Budgeting for initial set up is very important as this will be helpful to save some money in the initial stages. Make sure to have a good transport facility and it is better to build a farm near to local markets. Poultry farming equipment can be bought in second-sale to save some bucks. A proper plan is required with all mandatory things to be included. Daily labor is needed for farming work.

In case of going for a bank loan or applying for any scheme, contact the nearest bank for poultry loan and procedure. There are some financial and technical requirements to meet bank loan approval.

In many places, contract farming is available where they provide everything from feed to vaccination and wholesale purchase under one roof. The farmer has to provide only housing, water, power and a person to work there. They pay per kg of meat for every batch. This is very good for people who don’t want to take much risk and requires low investment.

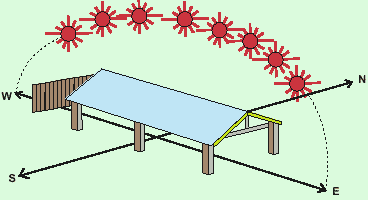

Things to Consider While Building a Poultry House (Shed):

Good and suitable housing play a prime role in raising all types of poultry birds. Some birds grow and live happily in the floor of poultry house and some in cages. Depending on the birds, you have to make a suitable house for your birds. Consider the following factors while building a poultry house or shed.

Always keep sufficient space in your poultry house, depending on the birds. So that your birds can live, grow and produce happily. Should never over-dense the poultry house and house must have a good ventilation system and should have sufficient flow of fresh air and light inside the house.

If you are planning for commercial poultry production, should consider keeping the proper distance between one house to another. It is recommended to clean the house and equipment on a regular basis and sterilize the house before bringing new birds/chicks into the farm. Make sure to have steps for preventing all types of predators and harmful animals. Temperature management is very important so that your birds do not suffer by excessive heat or cold. House or shed should have proper drainage system inside so that the cleaning of the house would be easy.

Establish your farm in a calm area and make sure the transporting bird’s without any hassle.

Equipment in Poultry Farming:

The main equipment needed in poultry farming for both layers and broilers is given below.

- Incubation Equipment: Setter, Hatcher, Compressed air system, Emergency standby electric plants and Hatchery automation equipment.

- Egg Handling Equipments: Hatching egg trays, Hatching egg transfer machines and egg Candler.

- Brooder Equipment: Charcoal stove/kerosene stove, Gas brooder, Electrical brooder, Infra-red bulbs, Reflectors/ Hovers, Brooder guard/chick guard and Electrical heaters (heating rods or coils).

- Feeding Equipment: Automatic feeder, linear feeder, Circular feeder, Shell grit box.

- Water Equipment: Water softeners, filters, and water heaters.

- Watering Equipment: Pan and Jar type, Linear waterer/Channel type waterers, Water basin made of plastic/wood/GI with grill, Nipple drinker, Bell type automatic waterer and Manual drinker.

- Vaccination Equipment: Syringe with needle/vaccine droppers, Automatic vaccinator and Fowl pox vaccinator/lancet.

- Miscellaneous/Other Equipment: Beak trimmer, Nest boxes, Weighing machine, Perches / Roost, Rake, Sprinkler, Sprayer and Flame-gun (Blow-lamp).

Layer Poultry Farming:

The poultry birds which are raised for egg production are called layers. A commercial hen generally starts laying eggs at the age of 12 to 21 weeks. They start laying eggs regularly at their 25 weeks of age. After 70 to 74 weeks of age, egg production of layer birds gets reduced. For commercial layer poultry farming, farmers generally keep the hens for 12 months from their first laying period. And then sell them for slaughter (meat) purpose. For commercial egg laying poultry farming systems, the environmental conditions are often automatically controlled by the producers. For a simple example, the presence of light helps the bird for laying eggs earlier. So, the producers should provide more lightening period to increase the probability of beginning of laying eggs. Usually, the egg-laying birds lay more eggs in warmer months than the cold months. So, it is recommended to keep the temperature of the room moderate will be very helpful for better egg production. Some commercial layer chicken breeds may produce more than 350 eggs a year. Layer poultry is raised in various methods of systems.

Broiler Poultry Farming:

The birds which are raised for commercial meat production are called broiler poultry. By using intensive farming methods, broiler chickens become suitable for consumption within their 5 to 6 weeks of age. Deep litter is the common raising systems in commercial broiler poultry farming.

Advantages of Broiler Farming Over Layers Farming:

Broiler farming is preferred for the following reasons.

- The initial investment in Broilers is less than layer farming.

- Broiler rearing period is 5 to 6 weeks only.

- Number of broiler chicken flocks can be raised in the same shed.

- Broiler chicken has high feed conversion efficiency rate i.e. the amount of feed required for unit body weight gain is lower in comparison to other livestock.

- Farmers can expect faster returns from the investment made in broilers.

- Market demand for broiler chicken is more compared to other livestock meat.

Housing/Shed Systems – Farming Methods in Poultry Farming:

Usually, there are 4 systems followed in commercial poultry farming.

- Free-range or extensive system.

- Semi-intensive system.

- Folding unit system.

- Intensive system:

- Cage system.

- Deep litter system.

However, the most common system followed is Cage system and Deep litter system under an intensive system.

-

Free-Range or Extensive System In Poultry Farming:

This method is the oldest one and has been used for centuries by general farmers. This is suitable where there is no shortage of land. In this free-range system, can find an appreciable amount of food in the form of herbage, seeds, and insects, provided they are protected from predatory animals and infectious diseases. Currently, nobody is using this system as a cage and deep litter system (intensive) has many advantages over this.

-

Semi-Intensive system:

Generally, this system is suitable and adopted where the extent of free space available is limited, but it is necessary to allow the birds 20 to 40 sq.yards/bird of outside run. Wherever possible, this space should be divided giving a run on either side of the house of 10 to 20 sq. yards/bird, thus enabling the chickens to move onto fresh ground.

-

Folding unit system:

This folding system of housing is an innovation of recent years. In portable folding units, birds being confined to one small run, the position is changed every day, giving them fresh ground and air and the birds find a considerable proportion of food from the herbage are healthier. In this system, the disadvantages are that food and water must be carded out to the birds and eggs brought back, so there is some extra labor involved in the regular moving of the fold units. This increases the cost and maintenance of the farm. The most convenient folding unit suitable to handle is for 25 hens. Usually, a floor space of one sq.ft should be allowed for each bird in the house, and 3 sq.ft /bird in the run, so that total floor space to the whole unit is 4 sq.ft /bird, as with the intensive system. A suitable measurement for a folding house to take 25 birds is 5 feet wide and 20 feet long.

-

Cage System:

The cage system used in rearing birds has been considered as a super intensive system providing a floor area of 450-525 sq.cm. (0.6-0.75 sq.feet) /bird. In this system, the birds are kept in 1, 2 or 2 per each cage, arranged in single or double or triple rows.

The main advantages of the cage system are given below:

- It allows to a rear greater number of birds per unit of area.

- Facilitates correct maintenance of records of birds.

- This system helps in identifying poor producers and prompts culling.

- This system control of vices of poultry cannibalism and egg eating.

- This system helps in the production of clean eggs and removing stress factor.

- This system of the housing allows easy control of parasitic disease like coccidiosis and worm infestation.

- In this system, one can take prompt steps to control feed wastage.

- This method of housing is ideal in the regions of moderated climate conditions where the day time temperature in summer does not high and temperature does not fall too low.

- Layers put in the cage system proved to be having more egg production than in the deep litter system.

- Feed efficiency and egg weight were better in caged birds than the laying flock under deep litter system.

Disadvantages of cage system are given below:

- It is difficult to ensure proper ventilation to birds especially in summer and under very high dense conditions.

- In this system, an incidence of a leg problem, fatty liver syndrome, cage layer fatigue, flies and obnoxious gases in the house will be on increases.

- Deep Litter System: Deep litter system is commonly practiced by poultry keepers throughout the world.

Advantages of a deep litter system in poultry farming:

- It is an economical and does not involve much investment.

- This system is hygienic, comfortable and safe to birds.

- Built up litter supplies vitamin B12 and Riboflavin to the birds.

- This system controls diseases and vices.

- This system increases the efficiency of production.

- In this system, paddy husks sawdust, chopped straw, dried leaf, and groundnut kernels can be used as litter materials.

Consider the below points while adopting a deep litter system.

- The deep litter system should always kept dry.

- Only the right numbers of birds should be housed.

- The house should be well ventilated with proper airflow.

- The litter should be stirred at least once in a week-wet litter if any should be replaced immediately with new dry litter and birds must be fed a balanced ratio.

- The time starting deep litter system should be in the dry period of the year as it allows sufficient time (At least two months) for bacterial action.

- Placing of water should be given due attention to keep litter dry.

Poultry Rearing Confinement:

- Size of Birds Flock in Poultry Farming: Larger size units are more economical than smaller ones under commercial conditions. A unit of 2000 layers is usually considered as economical for commercial egg production. In the case of broilers, a unit intake of 250 chicks per week is usually considered as viable.

- Stock in Poultry Farming: It is important to procure the best quality chicks from hatcheries. More profit can be made in a commercial unit by procuring day old pullet chicks. In broiler units, straight-run chicks would give an equally good performance.

- Poultry Performance Test in Poultry Farming: Sample test units for layers and broilers in the specified locations of your region might have established. The test results are published annually and give information about the performance of the various strains and breeds of chicken under identical conditions. This information would help in the choice of the stock.

- Number to be procured in Poultry Farming: In determining the number to be procured, normal losses that might occur due to death and culling have to be allowed. For each 1000 layers to be housed, procure 1100, day-old pullet chicks or 1050 growing pullet chicks or 1000 ready-to-lay pullets. In the case of broilers, the corresponding number would be 250-day-old straight-run chicks for 250 broilers to be marketed at 6 to 7 weeks of age.

- Artificial Brooding in Poultry Farming: Chicks newly hatched out require supplementary heat till they grow feathers. The period of brooding is usually up to 4 to 5 weeks of age and a little longer in cold season. Artificial brooding can be carried out in deep litter system of houses or in electrically operated brooder batteries.

- Floor space, feeding space and watering space for chicks

| Age weeks | Floor space Sq.ft./Chick | Feeding space inches/chick | Watering space inches/chick |

| 1 | 0.2 | 1.5 | 0.5 |

| 2 | 0.2 | 2.0 | 0.7 |

| 3 | 0.3 | 2.0 | 0.7 |

| 4 | 0.4 | 2.5 | 0.8 |

| 5 | 0.6 | 2.5 | 0.8 |

| 6 | 0.8 | 3.0 | 1.0 |

| 7 | 0.9 | 3.0 | 1.0 |

- Temperature requirement of chicks during different ages

| Age in weeks | Temperature under hover, at 5 cm above the floor ( °C) |

| 0 to1 | 35 |

| 0 to2 | 32 |

| 2 to 3 | 29 |

| 3 to 4 | 26 |

| 5 to 5 | 23 |

- Litter management in Poultry Farming: Litter materials such as sawdust, wood shavings, paddy husk, peanut shell, paddy chaff, chopped straw and such other materials that absorb moisture well can be used depending upon the cost and availability in your area. Litter should be spread to a depth of 5 cm on the floor before introducing chicks on the floor and build it up to a depth of 15 cm by adding litter material, at the rate of about 2 cm per week. This would require approximately 10 kg of litter material/square meter. Litter should be raked thoroughly at frequent intervals at least twice a week during the cold and rainy season, once a week during the hot season and the day after de-worming of the chicks. Litter should be kept dry always. During the cold and rainy season and on the area of the floor where watering utensils are placed, special attention should be given daily to check the litter condition. If required, top-dress with fresh litter. It is desirable to use dry lime at the rate of 10 kg per 10 m3 and rake the litter.

- Light in the House: Artificial light should be discontinued from the time the chicks no more require additional warmth. The dim light of a 40-watt bulb for every 200 to 250 chicks can be provided during the night for broiler chicks.

Feed Requirement in Poultry Farming:

Approximate Feed Consumption of Broiler Farming:

|

Spacing in meters |

Area in Hectares |

||||

|

Chicks age in days Day-1, Day- 2, Day-3, and Day-4 Day -5 Day-6 Day-7 Day-8 Day-9 Day-10 Day-11 Day-12 Day-13 Day-14 Day-15 Day-16 Day-17 Day-18 Day-19 Day-20 Day-21 Day-22 Day-23 Day-24 Day-25 Day-26 onwards Feed Weight in grams 20 gm/bird/day, 22gm/bird/day 24gm/bird/day, 26gm/bird/day 28 gm/bird/day 30 gm/bird/day 32 gm/bird/day 34 gm/bird/day 36 gm/bird/day 38 gm/bird/day 40 gm/bird/day 42 gm/bird/day 44 gm/bird/day 46 gm/bird/day 48 gm/bird/day 50 gm/bird/day 52 gm/bird/day 54gm/bird/day 54gm/bird/day 56gm/bird/day 58 gm/bird/day 60 gm/bird/day 62 gm/bird/day 64 gm/bird/day 66 gm/bird/day 68 gm/bird/day Body Weight gain/day 45 – 55 gms, 55 – 95 gms, 95 – 135 gms, 135 – 175 gms. 175 – 215 grams. 215 – 255 grams. 255 – 295 grams. 295 – 335 grams. 335 – 385 grams. 385 – 425 grams. 425 – 465 grams. 465 – 505 grams. 505 – 545 grams. 545 – 585 grams. 585 – 625 grams. 625 – 665 grams. 665 – 705 grams. 705 – 745 grams. 745 – 785 grams. 785 – 825 grams. 825 – 865 grams. 865 – 905 grams. 905 – 945 grams 945 – 985 grams 985 – 1,025 grams 1,025 – 1,045 grams. |

|||||

The minimum requirements for protein, calcium, and phosphorus in poultry feeds are shown in the below chart. Remember, chickens raised for egg production are fed pullet-type diets, not broiler diets, regardless of being from broiler or egg-type.

| Minimum requirements |

Protein % |

Calcium % |

Phosphorus % |

| Broilers | |||

| Starter (0-6 weeks) | 23 | 0.9 | 0.5 |

| Finisher (6 weeks to market) | 10 | 0.8 | 0.5 |

| Pullets | |||

| Starter (0-8 weeks) | 20 | 0.9 | 0.5 |

| Developer (8 to 20 weeks) | 14 | 0.8 | 0.5 |

| Laying Hens | |||

| Layer | 16 | 3.0 | 0.5 |

Types of Poultry Feed:

| Age of chicks | Feed Type |

| 0 – 10 days | Pre-Starter |

| 11 – 21 days | Starter |

| 22 days – Till marketing | Finisher |

Application of Effective Micro-Organism Liquid (E.M.) in Broiler Farming:

Effective Micro-Organism (E.M) is a brown color concentrated liquid produced from the cultivation of 80 strains of beneficial microorganisms collected from the natural environment.

What are the advantages of E.M. Technology in livestock production or in poultry farming?

- It reduces cost inputs more efficiently and improves gain in body weight.

- It maintains a better health condition of chicks.

- It helps clean shed, less flies, ticks and less disease incidence.

E.M. in Broiler feed on a daily basis:

| Age of birds | E.M. Bokashi |

| 01 – 07 days | 30 grams/ kg feed |

| 08 – 14 days | 20 grams/ kg feed |

| 15 days onwards… | 10 grams/ kg feed |

E.M. Solution as an additive in drinking water on a daily basis:

| Age of bird | E.M. Solution |

| 01 – 14 days | 1 ml/ liter of water |

| 15 days onwards | 0.5 ml/ liter of water |

Caution Note:

E.M. solution should not be mixed with anti-biotic, disinfectants / chlorinated water. Contact any agriculture university or department of agriculture for detailed feed and nutrition requirement in poultry farming.

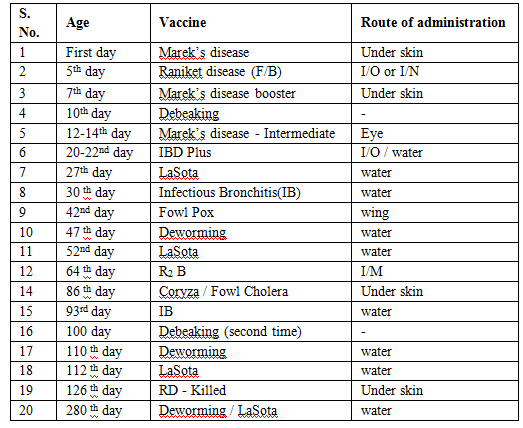

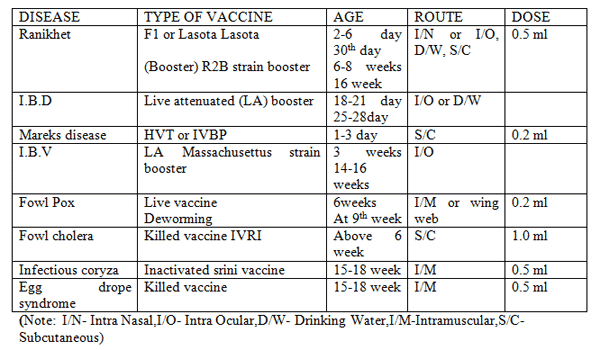

Vaccination Schedule in Poultry Farming:

The Following chart shows the chart for vaccinations in chicken.

Diseases in Poultry Farming:

For diseases , symptoms and their control measures, click here.

Loan or Scheme For Poultry Farming:

Check with local banks about poultry loan procedure. Most of the banks or financial institutions have certain guidelines to meet the loan eligibility requirement. Farmers should meet some technical and financial parameters to get the loan or scheme approved.

Marketing of Poultry Products:

Marketing of poultry products is very easy as they can be sold in the nearest markets or can hire any local agent to market the products. Large scale commercial poultry farms are approached by local/national chicken companies as well. Most of the regions in Asia have established markets for poultry products.

Bottom line in Poultry Farming:

Practicing good farming methods, daily care of birds, visiting nearby poultry farms, watching poultry farming videos in YouTube, getting training in poultry farming, getting tips and ideas from agriculture departments will be helpful in succeeding in the commercial poultry farming business.

For Quail Bird Farming: Read here.

For Sheep or Goat Farming: Read here.

For Indian Agriculture Guide: Read here.

Dear Sir,

Your article is very educative and I shall like to extend my network as a farmer by connecting to your organisation as well as follow up on your agricultural events. Thank you.

Thank you for your kind words. Please share this blog in your circles and help farmers indirectly. Keep visiting the site for more updates.

Good work done. However, how can i get the E,M solution .I am residing in Nigeria and if possible, how do i order for it and the cost per bottle?

Thanks.

Hi, We are based out of India. It is better to search online like eBay, Amazon or any of your local online stores. Keep visiting the site for more updates.

Here is some information about EM Solution.

It is very helpful to start my own poultry farm.

Thanks for publishing a detailed and educative article. I want to do some short course/training on establishing a poultry farm in NCR (District Ghaziabad, UP), Could you please give the details of the institutes/source of such theoritical/practical knowledge?

Sir, I will start 2000 birds layer farm, how much the investment required?

Good day sir

My virendar singh from Rudrpur I’m planning to start 2500 birds chicken farming how much investment and pls give Rudarpur agency no